Ok I have made this work so good, way better than I ever thought possible.

I'm sure there is a simpler way to do this like recalibrating the voltage divider or adding hysterisis to Q13, but this is the way I did it. There are still divided waves, but having 2 or 3 times the speed won't cause the trans to shift in fourth gear it will be like 5km/h

I was ready to coat the board because I soldered insulated wires to every components I wanted to adjust and will be able to adjust later if I feel the need, I would have cooked the board with my 35w iron and my lack of soldering experience.

You ask if I have tried filtering, yes I did, but the high speed spikes would go right trough, increasing masking and lag could remove some and not all, but made the speed unusable, I still don't understand how the other trans are not doing this, it may be my particular sensor.

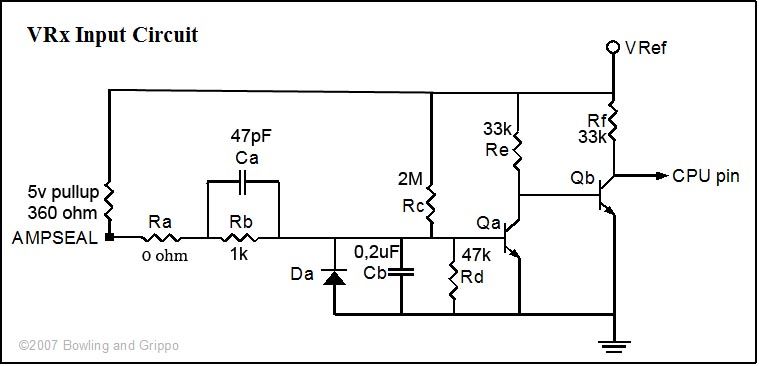

The problem came from noise when Q13 barely triggers, I'm definitely using this circuit under it's design, but very few people are running those transmissions without their tailshaft or transfer case (try to find a passenger side TC on a GM), I haven't really seen the noise on the output because I did not stretch the output enough to see high frequency spikes at both edges of the VR1 output, I could see it on the ground side of the Q13 output.

Having the schematic helped me so much with the brief description of what the components do, so I started to increase the size of the C28 capacitor, I used the spares 0,1 uF and it almost removed everything, I have put another in paralel, it did better, another, well no I took it off, it ended up with a value 0,2 uF, now I can rotate very slowly.

The pullup is also very necessary

I have made a video of the scope, you need to go full screen and switch to HD, note that I don't know the ratio between the cable drive and the driveshaft so I have put 10 tooths, I will adjust later, I was using 85 % mask, 4 lag, min speed 1 max 160 so basically no filtering, since it did nothing for my problem I removed it to try to make the hardware right first. I have made the problem happen by hand first to show that it was not only the drill motor ( but sometimes made it worst)

http://www.youtube.com/watch?v=yujxL1OGPoQ

Here's my work of art (the photography)

I will try the board before I coat it as soon as the Jeep is drivable and report here, but I would like to know if hardware store lacker, or the epoxy that I use at work to make plugs on pressurised cables and clear phone cable ends works since I have a box that has passed it's expiry date and I can't use it on the network (http://www.chemque.com/pages.php?page=R ... g_Compound), it stays soft but it's not hard to remove, digikey don't seem to have anything and driving to Quebec city is 120km, can I coat everything, processor, header, heat sink ( I can brush around)

Sorry for the long post but I hope it can help others that have similar needs

Cheers

Giovanni Boezio